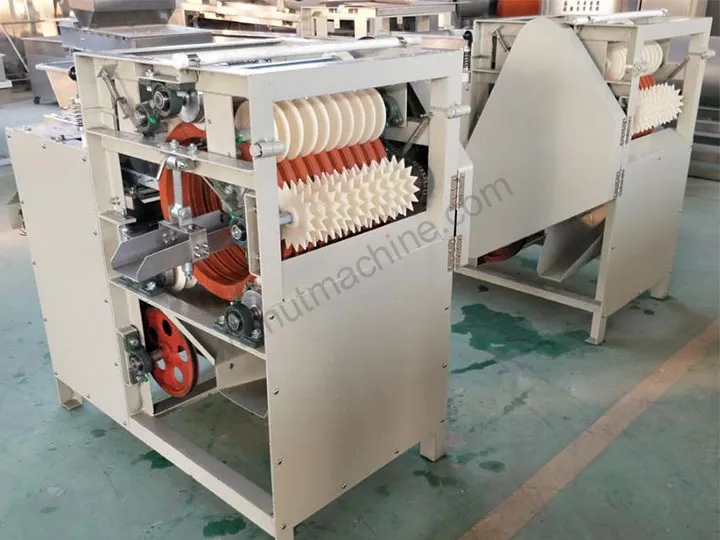

آلة تقشير الفول السوداني من النوع الرطب

آلة تقشير الفول السوداني من النوع الرطب هي قطعة مخصصة من…

آلة تقشير الفول السوداني من النوع الرطب هي قطعة معدات متخصصة مصممة لإزالة القشرة الحمراء من الفول السوداني المنقوع بطريقة لطيفة وفعالة. على عكس آلات التقشير الجافة، يلين هذا الأسلوب الرطب القشور من خلال نقع الماء الدافئ ثم يزيلها باستخدام أسطوانات مطاطية ناعمة، مما يحقق تقشيرًا نظيفًا مع أقل ضرر للنواة. هذا يجعل الآلة مثالية لمصنعي الأغذية الذين يحتاجون إلى نوى فول سوداني عالية الجودة، سليمة وناعمة.

المزايا الرئيسية لآلة تقشير الفول السوداني من النوع الرطب

استخدام آلة تقشير قشرة الفول السوداني من النوع الرطب يوفر العديد من الفوائد:

- معدل تقشير عالي: عادة 92%–98%.

- معدل الكسر منخفض ونسبة النوى الكاملة عالية: الكسور حوالي 2-3٪، مع 85٪-90٪ من النوى الكاملة.

- البذور المقشرة الناعمة والنظيفة: يظل الفول السوداني أبيض ومرتب، مناسب لمعالجة الأغذية عالية الجودة.

- فصل القشرة والنواة تلقائيًا: لا حاجة للفرز اليدوي، مما يحسن الكفاءة.

- نطاق تطبيق واسع: مناسب ليس فقط للفول السوداني ولكن أيضًا للصويا، اللوز، الحمص، البازلاء الخضراء، وأنواع أخرى من المكسرات والبقوليات.

- تصميم بسيط وانخفاض استهلاك الطاقة: سهل التشغيل والصيانة، مثالي للمصانع الصغيرة والمتوسطة لمعالجة الأغذية.

نظرًا لهذه المزايا، تُستخدم آلات التقشير الرطبة على نطاق واسع في مصانع زيت الفول السوداني، ومصانع معالجة لب الفول السوداني، وخطوط إنتاج الوجبات الخفيفة، ومنتجي مشروبات الفول السوداني، وأكثر من ذلك.

مبدأ العمل: كيف تعمل آلة تقشير الفول السوداني الرطبة

الخطوة 1: النقع

يُنقع الفول السوداني في ماء دافئ أو ساخن لبضع دقائق. هذا يلين القشرة الحمراء ويخلق فجوة صغيرة بين القشرة والنواة.

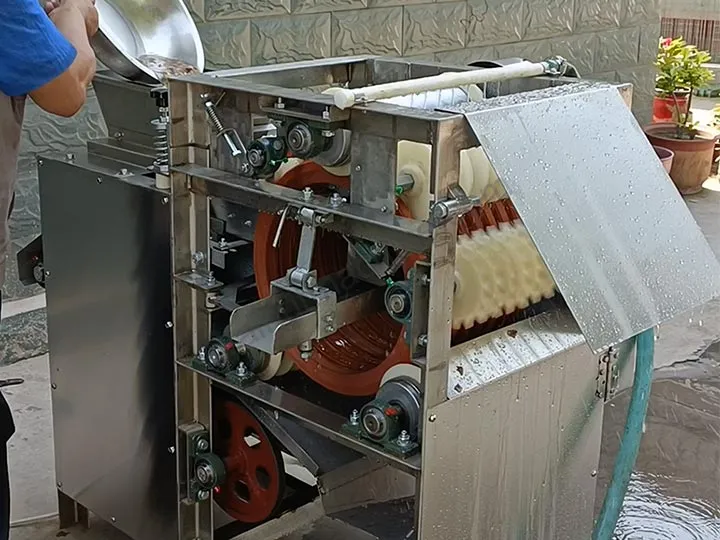

الخطوة 2: التغذية

يُسكب الفول السوداني المنقوع (مع كمية صغيرة من الماء) في حوض التغذية. ترسلها الهياكل الاهتزازية أو الموجهة إلى منطقة التقشير.

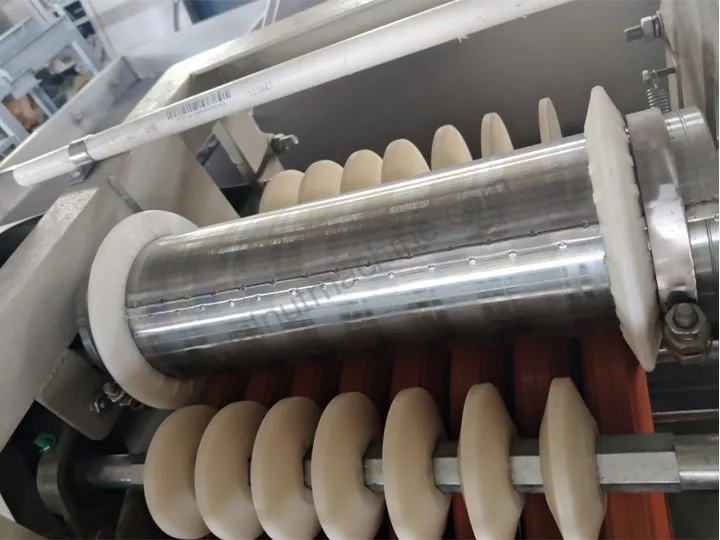

الخطوة 3: تقشير الأسطوانة المطاطية

تدور الأسطوانات المطاطية الناعمة بسرعة مضبوطة، وتفرك القشور برفق دون تلف النوى.

الخطوة 4: التفريغ التلقائي والفصل

يخرج النوى المقشرة من خلال منفذ واحد، بينما يتم فصل القشور المزالة وتفريغها من خلال مسار آخر.

كيف تعالج آلة تقشير الفول السوداني أنواع مختلفة من المكسرات؟

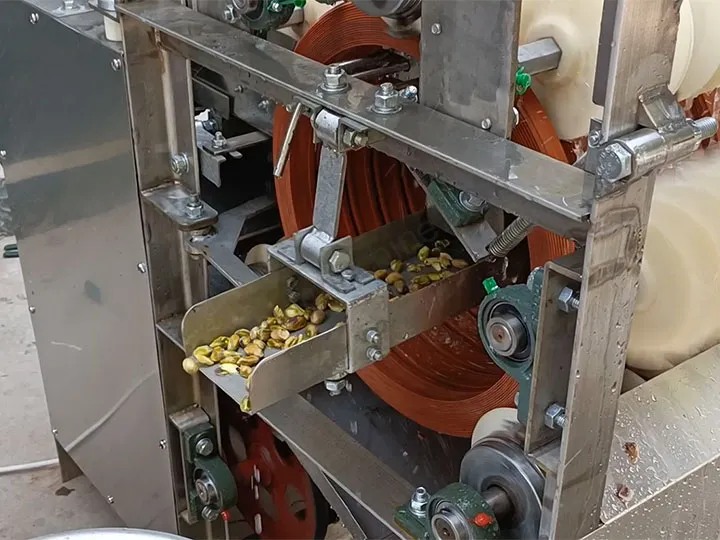

آلة تقشير الفول السوداني من النوع الرطب يمكنها أيضًا معالجة أنواع مختلفة من الفول والمكسرات

بالإضافة إلى الفول السوداني، فإن آلة تقشير الفول السوداني من النوع الرطب مناسبة أيضًا لتقشير العديد من المكسرات والبقوليات المنقوعة الأخرى. يمكنها إزالة القشور بكفاءة من اللوز، فول الصويا، الحمص، الفول العريض، الفول mung، وفول الوبار باستخدام طريقة تقشير الأسطوانة المطاطية نفسها. تتطلب هذه المواد فقط نقعًا مناسبًا قبل دخولها إلى الآلة، مما يسمح للمصنعين بمعالجة منتجات متعددة باستخدام جهاز واحد وتوسيع نطاق إنتاجهم بسهولة.

المعلمات الفنية النموذجية

فيما يلي المواصفات الشائعة لنماذج آلات تقشير الفول السوداني الرطبة الشعبية:

| معامل | نطاق |

| سعة | 100–150 كجم/س أو 200–250 كجم/س |

| معدل التقشير | 92%–95%. |

| معدل النواة الكاملة | 85%–90% |

| معدل الكسر | 2%–3% |

| الأبعاد (نموذجية) | حوالي 1180 × 720–850 × 1100 ملم |

تطبيقات آلة تقشير قشرة الفول السوداني الرطبة

تُستخدم هذه الآلة على نطاق واسع في مجالات المعالجة التالية:

- المعالجة العميقة للفول السوداني: نوى الفول السوداني، زبدة الفول السوداني، زيت الفول السوداني، مسحوق الفول السوداني، حليب الفول السوداني

- إنتاج الوجبات الخفيفة: الفول السوداني المقلي، الفول السوداني المغلف، الفول السوداني المتبل

- تقشير المكسرات والفول: اللوز، فول الصويا، الحمص، الفول العريض، الفول mung

- ورش صغيرة إلى مصانع صناعية: مناسبة لمختلف مقاييس الإنتاج

اتصل بنا للحصول على حل تقشير مخصص

إذا كنت تخطط لترقية خط معالجة المكسرات أو الفول، يمكن لآلة تقشير الفول السوداني الرطبة أن تقدم أداء موثوقًا لمجموعة واسعة من المنتجات. سواء كنت تعالج الفول السوداني، اللوز، الصويا، أو مواد منقوعة أخرى، يمكننا مساعدتك في اختيار النموذج المناسب بناءً على سعادتك واحتياجات التطبيق.

لا تتردد في الاتصال بنا للحصول على التفاصيل، الدعم الفني، أو عرض سعر مخصص. سيكون فريقنا سعيدًا بتقديم حل مناسب لمتطلبات إنتاجك.