Dry Type Peanut Skin Peeling Machine

Peanut skin peeling machine is specially designed for removing the…

Peanut skin peeling machine is specially designed for removing the red skin of roasted peanuts with a stable peeling effect and high efficiency. Also known as a roasted peanut peeling machine, it uses a dry peeling method to achieve a 96% peeling rate and a 6% half-kernel rate, making it suitable for peanut food processing plants.

What is the Dry Peanut Peeling Machine?

The groundnut skin removing machine is an advanced food processing machine that utilizes a dry method process, efficiently removing the skin from roasted peanuts without the need for water. This advanced peeling technology maximizes the preservation of the peanut’s original flavor and nutrients, making it an ideal choice for producing various snack foods and baked goods.

In contrast to the dry-type peeling process, our company also offers another peanut skin peeler, which is a wet peanut peeling machine. The wet peanut skin peeling machine removes the skin through blanching and friction, resulting in a smoother peanut surface. It is suitable for producing peanut butter, peanut paste, coated peanuts, and other products that require a high level of surface integrity.

Core Advantages and Technical Highlights of Our Peanut Skin Peeling Machine

- Stable and Reliable Performance: The machine adopts advanced rolling and rubbing peeling technology, ensuring stable operation during extended periods and reducing failure rates.

- Excellent Peeling Effect: A high peeling rate of up to 96% ensures clean peanut surfaces, enhancing the aesthetic appeal of the finished product.

- Extremely Low Half-Kernel Rate: With a half-kernel rate of only 6%, material loss is minimized, thereby improving economic efficiency.

- High Production Efficiency: Available in multiple models with production capacities ranging from 200kg/h to 1000kg/h, allowing flexible selection based on your production scale.

- Durable Quality: Utilizes national standard materials and components. The main unit’s outer casing is made of stainless steel, ensuring a robust structure and long service life.

- Easy Maintenance and Operation: User-friendly design facilitates daily cleaning and maintenance.

Working Principle: Fine Dry Rolling and Rubbing

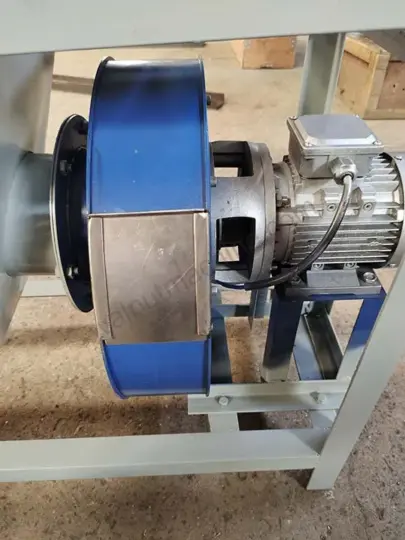

The dry type peanut skin peeling machine employs an innovative rolling and rubbing peeling method. After roasted peanuts are fed into the machine, they undergo gentle friction with specially designed abrasive rollers within the machine’s drum. This mechanical action effectively peels off the peanut skin. Simultaneously, a powerful built-in fan blows away the separated peanut skins and debris, resulting in clean, whole peanut kernels.

High-Performance Parameters to Meet Diverse Needs

We offer four different models of the dry peanut peeling machine to accommodate clients with varying production volume requirements:

| Modelo | Capacity (kg/h) | Motor Power (kw) | Fan Power (kw) | Weight (kg) |

| TZ-1 | 200-250 | 0.37 | 0.55 | 110 |

| TZ-2 | 400-500 | 0.37 x 2 | 0.75 | 200 |

| TZ-3 | 600-800 | 0.37 x 3 | 1.1 | 280 |

| TZ-4 | 800-1000 | 0.37 x 4 | 1.5 | 360 |

- Voltage Options: 380V/220V

- Frequency: 50Hz

- Peeling Rate: ≥96%

- Half-Kernel Rate: ≤6%

High-Quality Materials and Exquisite Craftsmanship

We understand the importance of equipment quality. The peanut skin peeling machine is crafted with meticulous attention to material selection and manufacturing processes:

- Main Structure: Features a robust frame made of national standard angle steel to ensure stable operation.

- Contact Parts: Key components such as the main unit casing and partition plates are made of food-grade stainless steel, offering corrosion resistance, ease of cleaning, and compliance with food safety standards.

- Core Components: Shaft rollers are precision-machined from 45# steel, balanced, and bonded with national standard Grade 1 abrasive material, ensuring efficient and uniform peeling.

- Transmission System: Transmission parts are made of carbon steel, coupled with national standard branded motors and bearings for strong power and smooth operation.

- Detailed Optimization: The fan impeller with fewer blades is designed for efficient discharge of peeled residue. Organic glass protective covers enhance safety. The fan residue cleaning door design simplifies maintenance.

Wide Applications of Peeled Peanuts

Peanut kernels processed by the dry peanut skin peeling machine, with their red skins thoroughly removed and kernels intact, are ideal raw materials for producing a variety of high-quality snack foods, such as:

- Salted Peanuts

- Cacahuetes recubiertos

- Fried Peanuts

- Mantequilla de cacahuete

- Various Baked Goods

Peanut Skin Removing Machine Price

When considering the peanut skin removing machine price, our dry peanut skin peeling machine offers multiple models to meet different production scales and specific operational needs. The final price will vary depending on the specific model you choose, its production capacity configuration, and any potential customization requirements.

To ensure you receive the most accurate and competitive quotation, tailored precisely to your factory’s needs, we sincerely invite you to leave your inquiry. Our professional sales team is always ready to discuss project details with you in depth, answer your questions, and provide you with a comprehensive quotation plan.